Top 5 Digital Printing Techniques You Need To Know About

Digital printing has revolutionized the way we produce printed materials, offering a wide range of techniques that cater to various needs and applications in today’s fast-paced industries. With advancements in technology, digital printing has become an essential tool for businesses and individuals to create high-quality prints quickly and efficiently.

In this article, we’ll explore the top 5 digital printing techniques that every designer, marketer, and print enthusiast should know about. Whether you’re a seasoned professional or just starting your journey into the world of printing, these techniques will help you achieve outstanding results and make a lasting impression. So, let’s dive in and discover the cutting-edge techniques that will take your prints to the next level.

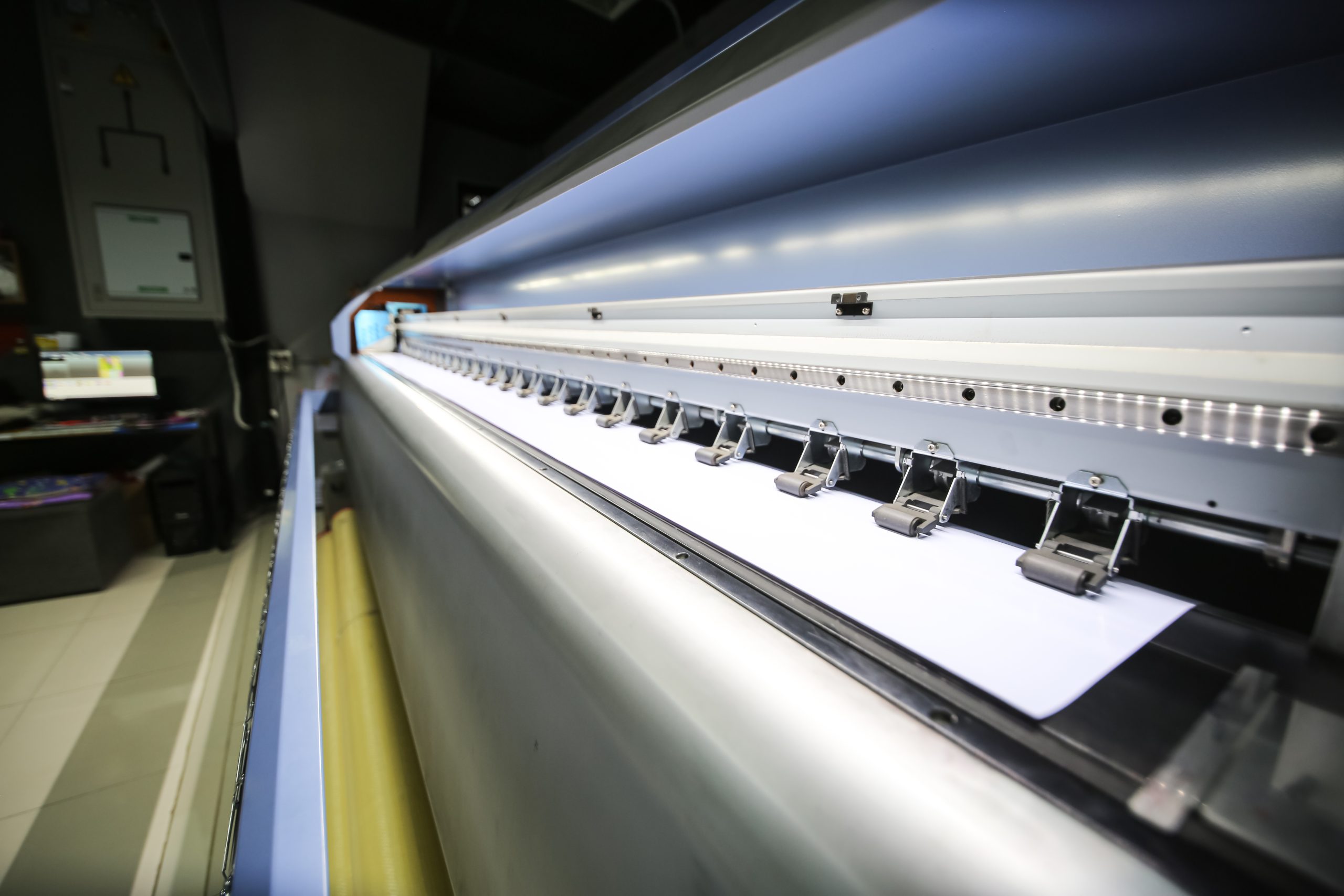

1. Inkjet Printer

Inkjet printers have become an indispensable tool in the world of digital printing. These printers utilize tiny droplets of ink to create high-quality images with precise details and vibrant colors.

One of the key advantages of inkjet printing is its ability to produce high-resolution prints, making it perfect for printing photographs, artwork, and other visual materials that demand exceptional image quality. The droplets of ink are sprayed onto the printing surface, resulting in sharp and crisp details that capture even the finest nuances.

Inkjet printers offer a wide color gamut, allowing for the reproduction of vibrant and true-to-life colors. This makes them ideal for producing marketing materials, brochures, and other visual collateral that needs to make a lasting impact. Whether it’s vivid hues, subtle gradients, or bold designs, inkjet printers can deliver stunning results.

2. Laser Printers

When it comes to digital printing techniques, laser printers are a popular choice for many businesses and individuals. These printers utilize a laser beam and a rotating drum to create high-quality prints.

One of the main advantages of laser printers is their ability to produce sharp and precise images. The laser beam creates tiny dots on the drum, which are then transferred onto the printing surface, resulting in clear and detailed prints. This makes laser printers particularly suitable for printing text, graphics, and images that require fine details and high resolution.

In addition to their exceptional print quality, laser printers are also known for their fast printing speeds. The laser beam scans the drum quickly, allowing for rapid printing of multiple copies. This makes laser printers a time-efficient option for businesses that require large volumes of printed materials.

3. Offset Printing

Offset printing is a popular method used for large print runs and high-quality image reproduction. It involves transferring an image onto the material through a printing plate.

The printing plate plays a crucial role in offset printing. It is usually made of aluminum and contains the image to be printed. The plate is chemically treated to attract ink to the image area and repel it from the non-image area. As the plate rotates on the printing press, ink is transferred to a rubber blanket and then onto the material, creating a high-quality print.

One of the biggest advantages of offset printing is its ability to produce superior image quality. This method can reproduce intricate details, vibrant colors, and smooth gradients, making it a preferred choice for printing high-resolution images. Additionally, it offers excellent color fidelity, ensuring that the printed colors closely match the original image.

Offset printing is versatile in terms of materials it can print on. It is compatible with a wide variety of papers, including glossy, matte, and textured options. It can also print on other materials such as cardboard, plastic, and fabric. This versatility makes it ideal for various applications, from business cards and marketing materials to packaging and promotional items.

4. Digital Textile Printing

Digital textile printing is a cost-effective and efficient alternative to traditional rotary screen printing. Unlike rotary screen printing, which requires the creation of screens and setup costs, digital textile printing utilizes print heads to directly print on the fabric. This eliminates the need for screens and increases the speed and accuracy of the printing process.

Digital textile printing offers a wide variety of materials that can be printed on. This includes popular fabrics such as cotton, viscose, wool, silk, and polyamide lycra. Whether it’s creating patterns on textiles for the fashion industry or printing designs on upholstery fabrics, digital textile printing provides endless possibilities.

5. 3D Printer

3D printing has revolutionized the manufacturing industry by offering a revolutionary method of creating physical objects. Using digital models, 3D printers are able to manufacture objects by adding material layer by layer, eliminating the need for special tools or molds.

The process of 3D printing begins with a digital model, which is created using computer-aided design (CAD) software or scanned using a 3D scanner. The digital model is then sent to the 3D printer, which interprets the design and builds the object layer by layer. The printer deposits material, such as plastic, metal, or even bio-compatible materials, to create the final product.

The applications of 3D printing are vast and continually expanding. One of the most commonly seen uses of 3D printing is in the production of promotion and marketing freebies. Companies can create customized giveaways, such as keychains or miniatures, to promote their brand or product. Novelty items, like customizable phone cases or decorative home items, are also popular uses of 3D printing.

Conclusion

In conclusion, selecting the right printing method is crucial for achieving desired results in terms of print run size, material, detail, and color. Digital printing is ideal for small to medium print runs due to its cost-effectiveness and ability to produce high-quality prints with a wide variety of materials. For large print runs, offset printing remains a popular method, offering efficient production and consistent printing quality.

Leave feedback about this